Toroidal transformers: the 5 mistakes to avoid when choosing and installing

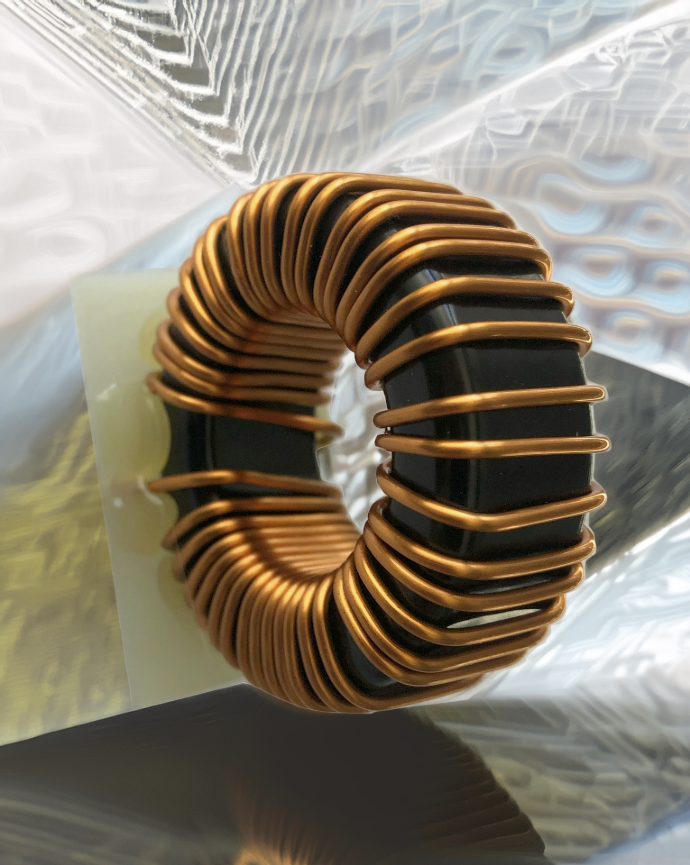

Toroidal transformers are today one of the most widespread solutions in the electrical sector due to their high efficiency, silence and operating stability. Their compact design and excellent magnetic performance make them ideal for professional applications, audio equipment and precision power systems.

However, to ensure reliability over time and optimal performance, it is essential to choose and install the toroidal transformer correctly. Sizing or assembly errors can compromise the safety of the system and reduce the life of the device.

Below we analyze the five most common errors to avoid when choosing and installing a toroidal transformer.

1. Underestimate correct power sizing

The first recurring error in selecting a toroidal transformer concerns the sizing of the nominal power.A chosen transformer with insufficient power compared to the real load can overheat, generate vibrations or reduce the overall efficiency of the system.In contrast, an overly oversized model results in unnecessary footprint, higher cost, and possible inrush current problems at startup.The correct choice of power must therefore be based on the actual load of the system and the operating conditions, considering a proportionate but not excessive technical margin.

2. Ignore the starting current when turning on

An aspect often overlooked in the use of toroidal transformers is the inrush current, which is the peak current that occurs when turned on.These devices, by their constructive nature, can generate a much higher initial absorption than the rated current.If not foreseen in the design phase, this can cause unwanted interventions by circuit breakers or fuses, as well as stressing the power lines.It is therefore essential to consider the starting current in electrical calculations, especially in systems with multiple transformers, choosing the appropriate protections and components compatible with this phenomenon.

Toroidal transformers: the 5 mistakes to avoid when choosing and installing

3. Do not consider thermal dissipation

Another common mistake involves heat dissipation.Although toroidal transformers are characterized by high efficiency, the power lost in the form of heat is not negligible, especially in continuous applications or in environments with high temperatures.Insufficient ventilation or installation in closed spaces without air exchange can lead to progressive overheating which affects insulation life and electrical performance.It is good practice to always provide ventilation spaces and a correct mechanical arrangement to facilitate natural heat dissipation and keep the transformer within the temperature limits permitted by the manufacturer.

4. Non-compliant mechanical assembly

The assembly phase is crucial for the correct installation of a toroidal transformer.The most frequent error consists in directly fixing the transformer to metal surfaces without mechanical insulation, or in excessively tightening the central bolt that crosses the toroidal core.Such practices can cause deformations of the magnetic core, generate acoustic vibrations or even compromise the electrical safety of the system.A compliant mounting must always include insulating washers and spacers that avoid direct contact between the transformer and the fixing surface, while at the same time ensuring stability and no noise during operation.

5. Neglect compatibility with LED or electronic load

One of the most critical errors concerns the electrical compatibility between toroidal transformer and the type of connected load, particularly in the case of LED systems Not all LED modules or drivers can be powered by alternating current (AC) or with a traditional transformer. In the presence of integrated electronic power supplies, dimmable systems or constant current loads, the use of a toroidal transformer can cause malfunctions, flickering or reduction in the useful life of the components.

For this reason it is essential to verify that the selected transformer is specifically designed to power the type of load expected, respecting the voltage and frequency characteristics declared by the manufacturer.

For over 20 years, Tector has been the point of reference for lighting professionals. contact us now for a consultation!